The general engineering practice of designing products for manufacture is known as Design for Manufacturability (DFM). This technique is practiced across nearly every engineering discipline. This article details common design principles used to improve manufacturability, such as using a multi-functional team, standardizing parts, and minimizing over-constraints.

Some of the expected benefits of incorporating these engineering principles include:

- Faster time to market

- Lower production costs

- Simpler Bills of Material and routings

- Preventing design flaws from reaching production

- Higher product quality

To paraphrase a classic Stephen Covey principle, start with the end in mind, where the end includes designing for assembly, testing, servicing, and manufacturability. Start with Nortech Systems, a full-service electronics manufacturing service provider. We will maximize the benefits of applying these DFM techniques and get you to the end of a successful production project faster.

Start With the End in Mind

Designing for manufacturability also needs to consider assembly, testing, and serviceability. The design engineer needs to confirm what testing may be necessary throughout the process to verify the functionality or output of the final item. The entire product lifecycle and serviceability requirements also need to be considered.

Designing an assembly that has to go through destructive disassembly to access components needing replacement during the testing phase or servicing is not a viable option. The main reasons for this are: 1) it can be difficult to perfectly align the components during assembly if they have to be destroyed in order to replace one, and 2) it significantly increases the likelihood of damage to the assembly during testing or servicing. It is generally preferable to design the assembly so that it can be easily disassembled and reassembled without damaging the other components. This typically involves adding features such as screws, bolts, or snap-fit connections that can be easily undone and redone.

This design aspect is somewhat counterintuitive to designing for assembly, where you typically want to minimize the number of fasteners and screws utilized. The key is to find the balance between cost, complexity, and functionality, and finding that balance is the true goal of DFM.

Employ Multi-Functional Teams to Ensure Manufacturability

Successful multi-functional teams will involve members from various disciplines and have the authority and responsibility to complete their assigned tasks. They will also ensure that product requirements are incorporated into the designs, manufacturing plans, and associated documents and data items. Multi-discipline teams should be comprised of customer and supplier representatives.

Cross-functional teams will eliminate the “throw it over the wall” mentality. Inputs from team members in both project engineering and manufacturing engineering are necessary right from the start.

You will need quality engineering input as the design progresses and near the start of production. Implementing a Poka-Yoke process at this point avoids inadvertent errors and leads to an increase in production yield and a reduction in rework or scrap.

Develop a Modular Design

When it comes to product design, modularity is essential. A modular design allows for easy expansion and modification, making it easier to future-proof the product. When developing a modular design, engineers must consider how the product will be used in the future and how changes in technology or the environment might impact its performance. By modularizing the design, engineers can create a product that is easily adaptable to new conditions and that can be easily updated as technology evolves.

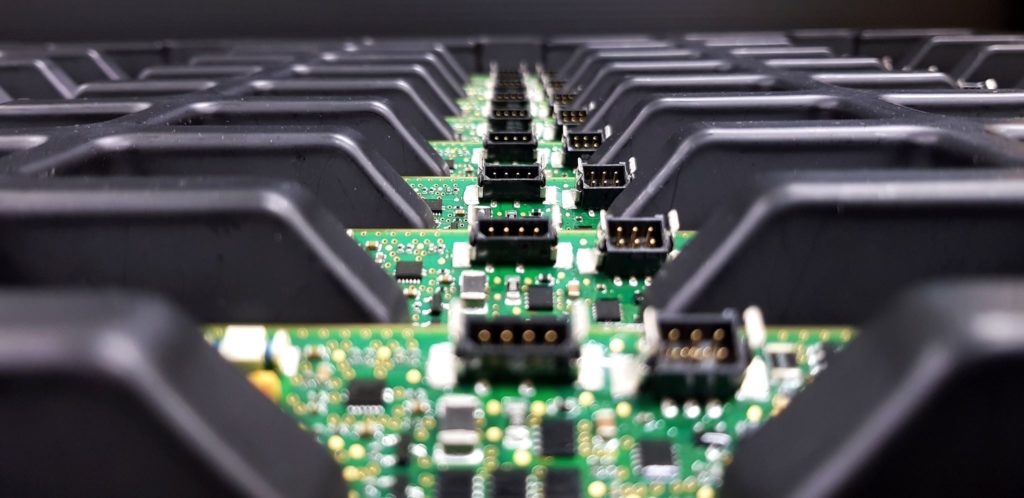

Utilize Standardized and Multi-use Parts

Using standardized parts provides several advantages, including improved quality and time-to-market. Standardized components reduce costs by allowing buyers to leverage economies of scale with suppliers. Placing blanket orders to be released as needed eliminates the need to hold large quantities of stock.

Designing with standardized and multi-use parts also allows you to reduce the overall cost of adding multiple new parts to inventory. And the best part about it is that it will also reduce the number of errors occurring during production.

Eliminate Overconstraints to Minimize Tolerance Demands

Layouts require reviewing for assembly compliance. Tolerances that are too tight may result in unsatisfactory results. A solution must be possible within the tolerance range, or it will be too costly to produce. Overconstraints occur when the design incorporates more constraints than the product needs to perform well.

Minimize Handling and Assembly Steps

In many cases, the fewer steps involved, the more efficient and cost-effective the manufacturing process will be. You do not want to design an item such that halfway through the assembly process, you need to re-orient the entire piece to access a different surface and orient it back to its original position. Additionally, designs requiring fewer steps are often more reliable and easier to troubleshoot in case of an issue.

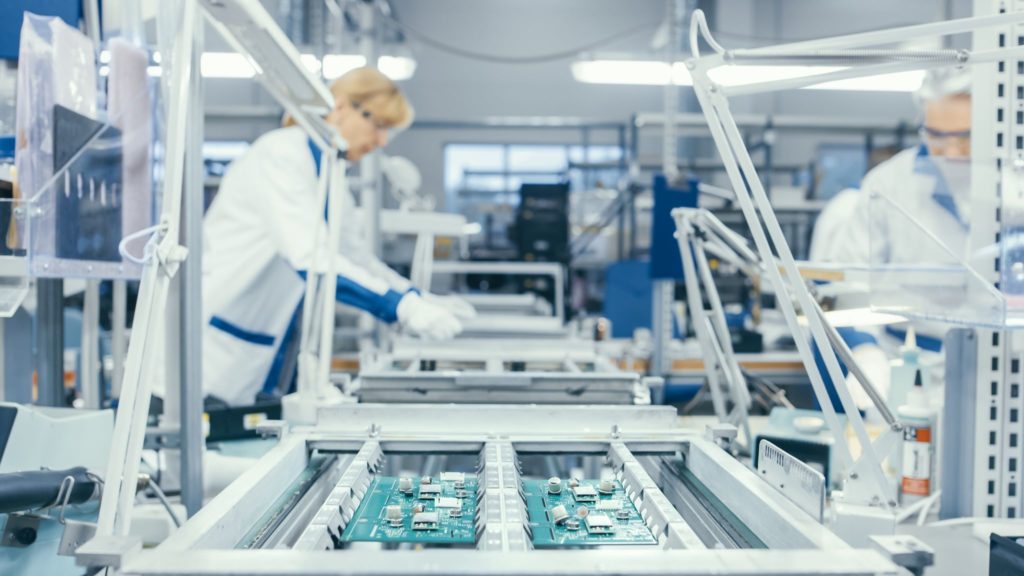

Find the Right Manufacturing Partner

When you have a design that you are ready to take to market, you need to find the right manufacturing partner. One with in-house engineering services saves time and money by having a single point of contact for all their engineering and production needs. The in-house engineers at Nortech Systems work with you to design and develop products that meet your specific requirements, provide valuable advice and support during the entire process, and ensure your products are produced on time and within budget.

Vertical manufacturing is another key strategic advantage for a manufacturing partner. Our services include sourcing materials and components and building individual systems at dedicated facilities for your products’ final assembly and packaging. This vertical manufacturing is advantageous because it reduces transportation costs and time, allows for better quality control, gives us more flexibility in product design, and provides seamless transitions between design, production, and assembly.

Finding a manufacturing partner with a quality management system (QMS) that is both robust and flexible will guarantee that your overall product quality and performance requirements are met. Setting quality objectives and developing plans to achieve them, monitoring and measuring progress towards those goals, and continually improving the QMS are the benchmarks for a successful manufacturer. Finding one that can balance having all the proper procedures defined and in place while still allowing for the flexibility to speed those procedures along benchmarks an outstanding manufacturer.

Contact Nortech Systems to find all these manufacturing partner traits for your complex product needs.